Tyumen pilot plant

|

| |

TPP Activities |  | |||

|

|

|

| |

Produced equipment | |||

|

|

|

|

Almost all equipment is manufactured according to the individual design. New goods made on the basis of the Company’s engineering know-how are put into production regularly.

Design and engineering division:

Design and engineering division is composed of:

- Tanks and vessels group

- Shut-off and control valves and metering equipment group

- Packaged equipment group

- Flaring and heat exchange equipment group

- Electrotechnical group

- Records group

Water treatment comprehensive technologies division is composed of:

- Group for process simulation and development of waste water treatment technologies

- Group for equipment design of comprehensive water supply and discharge systems

Heat exchange equipment design division is composed of:

- Engineering design group

- Engineering documentation group

Design and engineering division:

| | ||

| Design and engineering division is composed of:

| Water treatment comprehensive technologies division is composed of:

| Heat exchange equipment design division is composed of:

|

New goods developed according to in-house design are put into production on a regular basis. The majority of products comprises large-block turnkey equipment for the needs of gas production, processing, transmission and underground storage facilities: gas distribution plants and stations, start-up fuel gas treatment units for compressor and power stations, Vodopad electrocoagulating drinking water treatment stations, gas and condensate comprehensive treatment units, heat exchange and separation equipment, tanks and vessels. Engineering design used in equipment development is based on innovations, design and operation experience. It means that the customer receives equipment that meets all up-to-date requirements. |

Quality assurance is performed at all production stages by the Quality Control Service (QCS) that is composed of: laboratory for physical and mechanical testing, chemical analysis laboratory, non-destructive testing laboratory fitted with equipment for radiographic and ultrasonic inspection. |

| |

| ||

| Gazprom VNIIGAZ TPP specialists developed the following units: | |||

1. Thermal treatment unit on the basis of cyclone furnaces (reactors) with a daily capacity from 30 to 2000 tons designed for environmentally safe thermal neutralization of industrial and household liquid wastes; | 2. Thermal treatment unit on the basis of revolving furnaces (drum) with a daily capacity from 7 to 120 tons designed for environmentally safe thermal neutralization of industrial and household liquid and solid wastes; | 3. Thermal treatment unit on the basis of hearth furnaces (incinerators) with a daily capacity from 0,2 to 12 tons designed for environmentally safe thermal neutralization of industrial and household liquid and solid wastes. | |

Tyumen Pilot Plant of Gazprom VNIIGAZ LLC is a warranty of high quality at best price, individual approach and perfect fulfillment of contractual obligations.

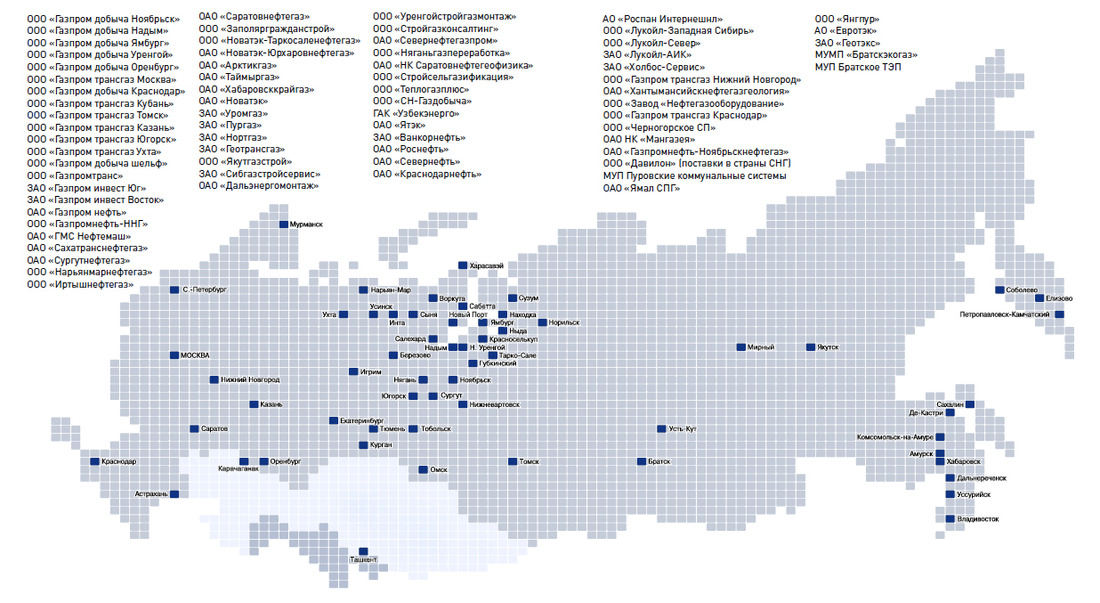

Business footprint