Research and test premises

Historical background

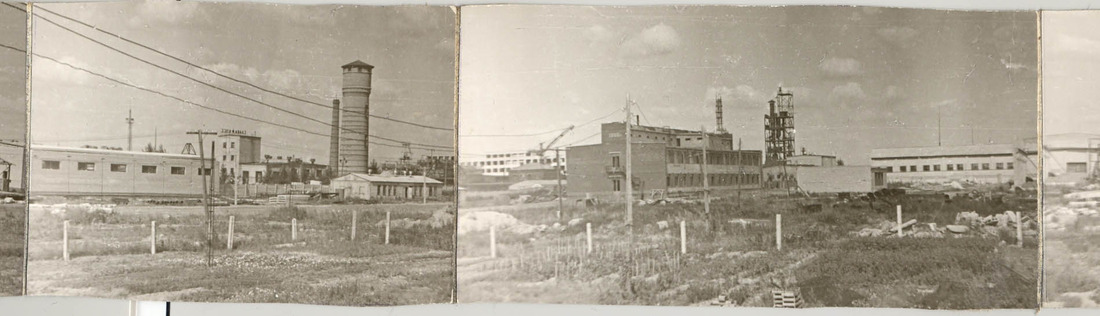

Demand for pilot test approval and further introduction of technological processes and equipment developed by the Institute was the reason to establish a special facility for that purposes in the ‘50s.

| 1952 Pilot unit for production of formaldehyde from natural gas developed under the supervision of N.N. Semenov, member of the USSR Academy of Sciences (Research Center for Chemical Physics), together with A.M. Markevich, A.B. Nalbandyan N.S. Enikolopov, as well as VNIIGAZ specialists A.N. Ivanov, A.A. Anisoyan and S.F. Gudkov confirmed rationale for construction of the pilot test facility to speed up implementation of the scientists’ ideas and lay-outs. | 1954 The first building was constructed for the management board and administrative department. The building arranged acetylene production unit and a unit for studying adsorption processes. | 1955 The test facility saw establishment of the Central Laboratory designed to perform comprehensive analytical control and component analysis of complex hydrocarbon mixtures, oils, resins, gas condensate, steels and other materials. |

| 1956 The first production workshop equipped with machine tools was built. This offered an opportunity to manufacture research units and equipment to study and develop technological processes. | 1962 The test facility was reorganized into VNIIGAZ pilot test plant by the decision of Glavgaz USSR. | ’60-‘70s These years evidenced staged development of the pilot plant’s production infrastructure, organization of divisions and sub-divisions with skilled specialists able to address tasks of the Institute’s scientific departments and the industry’s design companies. |

1996 The pilot plant was reorganized into VNIIGAZ Research and test premises, which shortly after became the structural subdivision of the Institute. | 2000s These years marked construction of the first start-up units at the pilot test facility within the R&D Center. The works encompassed development of the test bench to produce synthetic liquid fuels, reconstruction of the engineering and process infrastructure, and the start-up of the Environmental Protection Laboratory with a test unit for production of biological preparations. | 2006–2007 RTP engineering and technical staff together with scientists estimated the technical state of the production, research and test equipment of the Company. Estimation results helped to formulate work plans to upgrade equipment and bench units, develop design and process flow documentation for new and upgraded research and test bench units. This allowed RTP for working at full load during a long period of time. |

Research and test premises today

RTP territory (total area 9.65 ha) is provided with all necessary engineering networks and communications: | ||

branched network of process pipelines | electric capacities | structured cabled systems |

| own boiler house powered by natural gas | access and security systems | fire alarm and fire suppression systems |

The research and test premises is fitted with work places and provides all conditions for production activities: | ||

| 36 scientific laboratories and 15 research centers | 8 subdivisions of the Pilot Test Center | 4 subdivisions of the Building and Structures Operation Service |

Structural subdivisions:

| Corporate Center for formation systems research (cores and fluids)

| Corporate R&D Center for gas transmission systems and technologies

| Center for gas production technologies

|

| Corporate R&D Center for metrological support

| Corporate R&D Center for gas treatment, liquefaction and processing technologies

| Center for gas storage technologies

|

| Corporate R&D Center for tubular goods development

| Center for development and operation of fields located in the European part of Russia

| Center for MRB development

|

| Center for Standardization

| Corporate R&D Center for corrosion monitoring and processing

| Corporate R&D Center for welding and weld examination

|

| Corporate R&D Center for construction, operation and repair

| Center for well construction and repair technologies

| Corporate R&D Center for environmental safety and efficiency

|

| Pilot test center

| Buildings and structures operation service

|

Key business activities of research laboratories: | Infrastructure for applied experimental surveys and tests | |

|

| Laboratories and test sites of the PTF accommodate over 1300 units of lab, test, experimental and measurement equipment, and over 60 test and research installations. PTF territory also encompasses equipment of structural subdivisions committed to NSEE “VNIIGAZ —Certificate” CERTIFICATION CENTER, and a corporate core storage. |

Pilot Test Center

Description of the performed works

Pilot Test Center (hereinafter referred to as PTC) pertains to the category of Gazprom VNIIGAZ LLC subdivisions that work on an internal order principle and render fee-based services (works) for scientific, auxiliary and administrative Company’s departments. PTC is a multifunctional structural subdivision that comprehensively addresses research and engineering tasks different in terms of complexity.

Main PTC business activities:

|

|

|

|

|

|

|

|

Description of production infrastructure

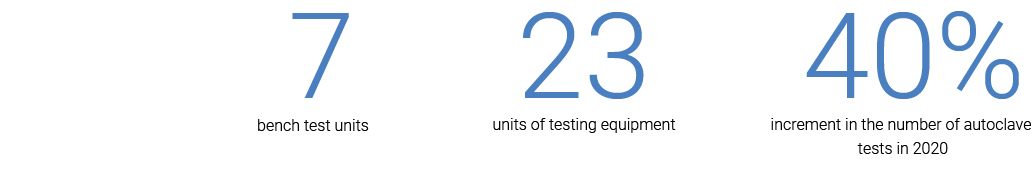

| The test room is fitted with 23 equipment units to test material specimens, and 7 test benches. | Workplaces of design and engineering staff are provided with computer-assisted design engineering tools. | Mechanical shop is fitted with over 130 blank, milling, turning, tool and cutter grinding, locksmith, welding, painting, drying, lifting equipment units, as well as non-destructive testing tools. |

| PTC technological capacity, highly-skilled regular labor force, engineers and technical assistants afford an opportunity to develop and produce items within a full work cycle, providing required quality and reliability in compliance with regulations, specifications and Rostechnadzor rules. | ||

Bench units and installations

| Equipment operated in PTC: | |||

|

|

|

|

|

|

|

|

| Equipment operated by scientific subdivisions: | ||

| Fermentative test bench to cultivate methane-oxidizing microorganisms (Corporate R&D Center for environmental safety and energy efficiency). | Test bench to produce broad-spectrum biological preparations (Corporate R&D Center for environmental safety and energy efficiency). | “Hermitage” calibration unit to check, calibrate, align, regulate and define tolerance of flow meters, liquid meters, flow rate-volume (mass) transducers for liquids of different types, including rotary meter (Corporate R&D Center for metrological support). |

| Bench to test and perform diagnostics of NDT equipment (Corporate R&D Center for corrosion monitoring and protection). | Test bench to study process and operation parameters of separation equipment (Center for gas production technologies). | Test bench to study hydromechanical parameters of well strainers (Center for gas production technologies). |

Enlarged photo (JPG, 412 KB)