We drive innovations! Interview to Gazprom journal on the Institute's development routes

| | Interview › Maxim Nedzvetskiy. Deputy Head of Department, Gazprom. Director General, Gazprom VNIIGAZ, LLC. Interviewed › Denis Kirillov Photos › Gazprom VNIIGAZ, LLC |

CENTER OF INNOVATIONS

| — Mr. Nedzvetskiy, Gazprom VNIIGAZ LLC is one of the flagship scientific assets of the Gazprom’s Group. What are the hallmarks of your Institute today? — Gazprom VNIIGAZ LLC is a scientific research Institute of natural gases and gas technologies. Currently, it fosters end-to-end R&D support of oil and gas projects along the whole value chain: from hydrocarbon prospecting, exploration and development to transmission, treatment and marketing of finished products. VNIIGAZ today is the principal PJSC Gazprom’s research center in terms of technologies. It administers a “single window” approach to implant innovative products. Comprehensive approach to problem solving has been the Institute’s outstanding feature since its start up. The Institute displays extensive expertise in all mainstream elements of PJSC Gazprom’s gas business, as well as in cross-disciplinary areas, including standardization, certification, metrology, digitalization, geoinformation technologies, corrosion protection, construction technologies, environmental and industrial safety. Human resources with their innovative potential, experience and knowledge are our main hoard of value. VNIIGAZ incorporates professionals from many regions of Russia. Our team numbers over 1.7 thousand specialists with an average age of 43 years. It stands to mention that in the last three years the Institute grew young again: 28% accounts for the young staff. Every sixth specialist has a PhD or DSc degree. | |

| | Strategy — What does Gazprom VNIIGAZ LLC development strategy imply? — Strategic priorities of our Institute are premised on the search for solutions and advancement of technologies able to address any challenges that the Gazprpom Group or the Russian gas industry face. They encircle significant complication of the mineral resource base, dynamic evolution of the gas transmission system and gas storage facilities, change in energy resources delivery destinations and methods, rapid development of end-to-end digital technologies, and of course decarbonization and climate neutrality. Responding to these challenges must be ensured predominantly by domestic technologies of the global level. In a point of fact, Scientific and Technological Development Strategy of the Russian Federation highlights that substantial changes take place in arrangement of R&D and innovative activities: contraction of the innovative cycle, blurring of disciplinary and industry borders, sharp increase in the volume of scientific and technical data, strengthening of qualification requirements, growing role of international standards. The pace of these changes is tremendous. But the Institute interprets them not as just challenges, but opportunities for a positive shift, which can be achieved through a corporate progress. Gazprom Group implements innovative activities comprehensively and consistently, and our Institute is a crucial element of that system. PJSC Gazprom’s Innovative Development Program till 2025 defines technological priorities to formulate an R&D Plan for the parent company. The Institute’s team completes around 45% of Gazprom’s R&D projects. |

Business profile

— What are the Institute’s key areas of activities?

— Around half of VNIIGAZ R&D projects are related to subsurface processes. Geoengineering modeling applied in strategic investment and production decision-making on effective field development is a mission-type objective. Today, we do author’s supervision of field development, which amounts for 92% of gas production in Gazprom’s Group. We set sights as high as 100% in the future.

Gas transmission, storage and processing infrastructure is the next pool of the Institute’s activities in terms of volume, constituting around one third of all projects. VNIIGAZ administers and develops the Unified Technical State and Integrity Management System for Production Facilities, which is of overriding priority, considering the age of the facilities and stringent industry safety standards.

Against this background, reconstruction and technical re-equipment are in special focus. The Institute develops related comprehensive mid-term target programs, annually approved at the level of PJSC Gazprom Management Board, and provides their scientific supervision.

Remaining 1/5 activities fall on cross-disciplinary areas, which by no means should be regarded as minor. Quite the opposite, as we have such competences available, the Institute is able to yield full-fledged application-oriented result.

— What is the Institute’s business footprint?

— VNIIGAZ business footprint is determined by geography of the gas industry, not only within the borders of our country. The Institute has good professional practice of collaboration with over 20 states from different continents. Today, we have contracts in force with our international partners.

We observe ever-increasing attention to our business from abroad. In October 2021, within the Russian Energy Week, Minister of Mines and Energy of Brazil, Bento Alburquerque, visited VNIIGAZ. In respect that PJSC Gazprom has a representative office in Brazil, we map out partnership development with our Brazilian colleagues.

However evolution of the Russian gas industry is our indisputable priority. The Institute has offices in the Moscow region, Uhkta, Tyumen, Lensk, Kazan, Stavropol, and Makhachkala. The short-range plans envisage opening of offices in Orenburg and Irkutsk. Effective and well-timed result requires to be close to production, which is a top-priority task of today.

— What are specific achievements of the Institute within the scope of each key area of activity? — The Institute returns over 1500 results annually. These are not only prospective research projects, but also front expert reports and recommendations of different levels, which are as well crucial for business.Mineral Resource Base — The Institute wrote PJSC Gazprom’s Mineral Resource Base Development Program for a long term. VNIIGAZ estimates and re-estimates reserves of the largest and prospective fields. For example, in 2020, Gazprom’s reserves increment totaled 486 bcm, whereas in 2021 it was expected at the level of 515 bcm. Geological exploration and formation systems research data are the basis for reserves calculation. | On a constant basis, VNIIGAZ elaborates new methodical approaches and instruments to increase accuracy and validity of customized studies of core samples and formation fluids. For instance, developed unit for core studies under P&T bedding conditions can both determine reservoir properties of pay zones, and the impact of different well completion technologies on the productivity of the penetrated section. This year evidenced development of three state-of-the-art mobile laboratory units to study the properties of produced resources. In the near future, they will be allocated at the production sites in East Siberia and on the Yamal. VNIIGAZ scientists provide R&D support of resource base development on the export routes, including ethane-containing gas to promote gas chemical production in Ust-Lug and Blagoveschensk. |

| Production — This year, design documents on the Urengoyskoye, Severo-Urengoyskoye, Astrakhanskoye, Zapolyarnoye, Bovanenkovskoye, Kovyktinskoye, Chayandinskoye, Kruzenshternskoye, Komsomolskoye, Vyngapurovskoye, Yety-Purovskoye, Obskoye, Pechorokozhvinskoye, Zapadno-Soplesskoye, Vuktylskoye fields have been updated. Design solutions for development and facilities construction of the Severo-Tambeyskoye field have been worked out for the first time. Different transmission and processing options for the unique Tambey cluster have been considered. Thus, 2021 saw solutions for Gazprom’s most important fields with initial total in place gas reserves over 30 tcm, and condensate reserves 2 bln tones. Further development of these prospects will provide 15.4 tcm of gas, and 880 mln tones of condensate produced. We participate in gas condensate feedstock production enhancement project on the Astrakhanskoye GCF. Our scientists authored the main design and engineering solutions intended at several-fold production increase on this field, which is the largest in the European part of Russia (4.2 tcm). Regarding its specifics, and first of all presence of acid components in the formation gas (hydrogen sulphide and carbon dioxide), field was developed at a low pace until recently (among other factors, environmental restrictions and marketing of gas sulphur, which is a byproduct of gas processing). Notwithstanding existing challenges, suggested design and engineering options helped to make a management decision on stage-by-stage enhancement of production and formation fluid processing on the Astrakhanskoye field in parallel with testing of new and never used technologies. This project also envisages deeper processing of formation feedstock and thus incremental benefit. |

The Institute carries out dedicated offshore studies, one of which this year was honored with PJSC Gazprom Science and Technology Prize 2021. Ice situation parameters of the Northern and Far-Eastern seas were collected and analyzed. For the first time ever, scientists developed and implemented a “full cycle” methodology of comprehensive studies of hydrometeorological, ice, and lithodynamic natural conditions within the whole aquatic area of the Sea of Okhotsk. This methodology is based on offshore re-analysis concept. The work resulted in unique hydrometeorological database, including sheet ice parameters used in service and repair of the subsea production unit of the Kirinskoye GCF. Reliable estimation of standard parameters was obtained for Yuzhno-Kirinskoye OGCF. It can be used when planning cluster development works for producing wells and designing field infrastructure facilities. |

| Gas transmission and underground gas storage — Over the last years, our specialists rendered R&D support of investment projects related to Gazprom’s gas trunkline construction (Nord Stream 2, Bovanenkovo-Ukhta, the Power of Siberia). VNIIGAZ performed calculations, which facilitated successful and timely packing of the offshore section of the Nord Stream 2 export gas pipeline. Consideration of dynamic loads and gas interaction nature during mutual displacement optimized duration of nitrogen supply and primary gas packing along with fulfillment of stringent requirements for the process safety. Full-time geotechnical models of underground gas storages are being actively developed and upgraded; the corresponding design documents are being updated. Prospective trends are also in progress. In particular, technologies of cushion gas partial replacement by non-hydrocarbon gases at underground gas storage facilities; construction of helium-rich natural gas storages (temporary, constant, operating) in the areas of helium production (East Siberia and the Far East). VNIIGAZ implements a feasibility study of prospective methane-hydrogen mixture transmission projects. Test operation of new transport facilities and equipment powered by liquefied natural gas and hydrogen is underway. | | |

Processing

— This year, our specialists were involved in development of technical solutions to organize separate natural gas processing from Karachaganakskoye and Orenburgskoye OGCF at the Orenburgsky gas processing plant, to construct new ethane units at Orenburg helium plant, and reconstruct ethane pipeline Orenburg — Kazan.

Development of a natural gas liquefaction test unit based on Gazprom’s technology with the use of domestic equipment inaugurated a flagship project for Gazprom VNIIGAZ LLC. The basic equipment has been produced, and now it’s being assembled at the Institute’s pilot test facility. Check-out of the natural gas liquefaction process at the new LNG test unit and practical demonstration of the efficiency of domestic equipment will facilitate the use of this technology at prospective natural gas liquefaction facilities.

This year was also dedicated to extraordinary strategic projects, which are future-proof in terms of state-of-the-practice. The possibility of producing lithium and its compounds, as well as other useful components from formation brines of Kovyktinskoye and Znamenskoye fields has been evaluated.

The results were reported at the meeting of Gazprom’s Board of Directors. The project of hydrocarbons and iodine production from industrial waters in the Krasnodar Territory is in the phase of active implementation. These two examples of import substituting production of strategic feedstock promote efficiency increase in the existing assets.

| Environment — Sensitive society’s perception of the global climate change problem affects competitive practices of the energy resource producers. Impact of greenhouse gas emissions on climate, although being not completely proved, is a constant point of issue and political decision-making. During the last years, the so called carbon footprint, which includes direct and indirect GHG emissions, is being actively evaluated. Traditionally, Gazprom VNIIGAZ LLC specialists have been in charge of methane, contaminant and GHG emissions from Gazprom Group’s facilities. Availability of a large volume of actual data obtained both by computational methods, and instrument measurements allow for unbiased carbon footprint estimation methodology. In particular, VNIIGAZ approach was used in carbon footprint estimation of natural gas supplies to Europe. There are plans to perform similar estimation and comparative analysis of different methods of gas supplies to China. Developed methodology is also used to evaluate a life cycle of vehicles powered by different types of fuels: gasoline, diesel, compressed natural gas, electricity. Moreover, we developed methodology to assess a toxic footprint of products to provide an unbiased evaluation of an extent of contaminant exposure on a human. The Institute evaluates carbon footprint of a life cycle of different types of power resources on a regular basis. Comparing biofuels, hydrogen and natural gas by this parameter surely deserves attention.On 15 November 2021, Rosakkreditatsiya made a resolution to accredit a nonprofit organization “Certification Center VNIIGAZ Certificate” (founder — Gazprom VNIIGAZ LLC) — greenhouse gases validation and verification body — in the national system. Organization confirmed its competences to perform validation and verification of greenhouse gases by eight declared types of economic activities: natural gas and oil production, onshore and pipeline transmission, production of petroleum products and gas carbon, production of chemical substances and products, supply of electric power, gas and steam, production of other non-metallic mineral output, metallurgical production, warehousing and support transport operations. CC VNIIGAZ Certificate is also engaged in products and services certification activities in INTERGASCERT voluntary certification system with the use of in-house information system that ensures traceability and transparency of certification works, time-saving and quality enhancement. | |

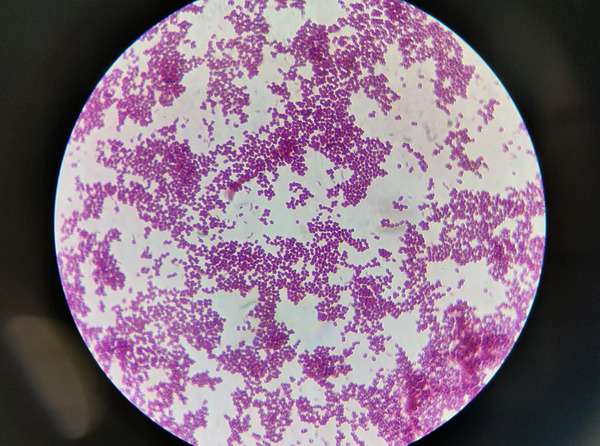

In parallel, over the last years our specialists have been involved in active development of nature-like technologies. These are biotechnologies that address challenges of the fuel and energy complex. For example, the Institute developed a series of biopreparations (biological product and biosorbent) to decontaminate soils and waters from petrochemicals without afterproducts of contaminations in a large temperature range (from +5 to 45°C) and 76–95% efficiency. VNIIGAZ also developed a biopreparation that enhances performance of the biological stage of sewage treatment facilities to treat waste waters up to the valid standards. Among other developments, there is a biopreparation based on urobacteria that helps to restore functional properties of construction materials able to increase bending strength by 20–23%, water resistance by 30–40%, and equally important to cut costs for repair works. The biopreparation successfully passed laboratory tests by reference samples and has plans for validation at well casing operations.

The Institute’s specialists created technology of bioprotein production (feed protein) from natural gas. We selected new strains of methane-oxidizing microorganisms to achieve crude protein content not less than 73% under optimum concentration of amino acids. This is above the well-known global equivalents, and allows declaring that there is a possibility to replace fish flour and soya with domestic products.— What works on hydrogen economy are underway at VNIIGAZ now?

— Today it is reasonable to consider hydrogen economy solutions along the whole market-logistical chain: from production, transmission and storage to application. Our Institute has competences in these areas and renders R&D services and support of PJSC Gazprom’s hydrogen projects. In 2021, VNIIGAZ established a subsidiary company Gazprom Hydrogen LLC to promote development of this business profile.

Preliminary design of the pilot hydrogen fueling station to be allocated within the premises of the AGZS 1 gas filling station of the Moscow Gas Processing Plant (AO MGPZ) nearby our Institute is currently in progress.

Together with Gazprom transgaz Samara LLC and single-purpose companies, the Institute carries out works on methane-hydrogen fuel use at gas compressors.| Results and plans — What are the bottom lines of Gazprom VNIIGAZ LLC activities over the last several years, and preliminary results for this year? — In 2018–2020, under the auspices of the parent company we implemented an action plan to stabilize financial and economic performance, and advance R&D activities. Through this process, budget revenues increased by 96%, and labour productivity per one employee by 84%, as compared to 2018. Two years in succession, we achieved positive financial outcome: 144.5 mln RUB revenues in 2019, and 130.3 mln RUB in 2020. We have expectations that this year our income will exceed the values of the previous year by 30% — over 6 bln RUB. We have plans to see 10 bln RUB income in 2022. Our Institute is actively upgrading the core assets and fitting departments with new equipment to promote further prospective development of the key business profiles. Investment expenses increased up to 370 mln RUB planned to be spent in 2021. This year, PJSC Gazprom approved mid-term initiatives on the Institute’s modernization, which means significant development of the research environment, and investment volume over 4bln RUB. |

| — What agenda have you prepared for 2022 and onwards? | |

— The Institute grows towards research and production complex of the full cycle. Over the last three years, we set up design bureau, we certified VNIIGAZ test center, and expect establishment of a full-scale plant as yearly as in 2022. Currently, reorganization of Gazprom projektirovaniye LLC and Gazprom VNIIGAZ LLC is at the stage of completion. This reorganization implies that Tyumen experimental plant will be separated from the first company with establishment of “Tyumenskiy eksperimentalny zavod” LLC (TEZ) with its simultaneous consolidation with the Institute in a status of a branch office named Gazprom VNIIGAZ Tyumen. Reorganization will generate a successful practice of feasibility expert review of investment projects, and unlock the interaction potential between the Institute’s R&D departments and TEZ design and production base, ensuring constant follow-through of test samples of innovative products till batch manufacturing. Our key projects are directly related to three basic vectors of prospective development: the Russian East, Yamal and offshore. To be more specific, we can mark several basic trends: replenishment of the mineral resource base to provide forecast production levels both in traditional gas production centers, and in new regions; development of production technologies for nonconventional gas resources (Senonian, gas hydrates, coal-methane reservoirs, etc); effective additional recovery of remaining reserves and field development at the stage of declining production; efficiency improvement of the development of hard-to-recover gas reserves with poor reservoir properties, including increase in hydrofracturing performance. As for gas transmission and storage, the main scientific and methodical issues are related to development of the gas transmission system of a new generation (14.8 MPa pressure); optimization of UGS operation system, cutting of unit costs for diagnostics of GTS facilities; reduction in specific gas consumption for BOP needs. Priority trends of gas industry development in the areas of processing and environment comprise effective production, transmission and storage of hydrogen and associated carbon dioxide; commercializing associated components (helium, lithium, iodine, sulphur); adaptation to climate change; development of nature-like technologies to ensure high reputation of natural gas and gas industry; technologies able to compensate negative impact on the environment. Data is a necessary feedstock to power the Institute’s business. Gazprom VNIIGAZ LLC faces a task to establish a unified center of R&D and technological information to implement smart processing systems for large data volumes. There is a dynamic progress in technologies related to space monitoring, which helps to effectively address industrial safety goals. | |

Future directions

— What are Gazprom VNIIGAZ LLC development routes?

— Development prospects are associated with overcoming the voiced challenges and searching for the best solutions for the Gazprom Group and our customers.

Success formula of the research organization is a product of three factors: human resources, research environment and demand. We arrange further progression of our human potential through scientific and educational center, and thesis boards. Educational activities is our hallmark. Moreover, terms of remuneration are competitive, and allow employing strong specialists.

All necessary decisions regarding improvement of the research environment have been made by PJSC Gazprom. It is remarkable that it happened in the Year of Science and Technologies declared at the government and corporate levels.

The third factor is demand. The nation’s and the Company’s leadership believe that “science is not a thing in itself”. Deliverables of our applied scientific activities should have a practical effect. New industrial revolution and the so called energy transition call for innovative technologies and effective technical solutions. It is true for Gazprom, and beyond its borders. That is why the Institute’s strategic mission is to provide a high quality level and expediency of results. And we’ll score a bull’s-eye, as we drive innovations!

issue № 12 (PDF, 13 MB)

Enlarged photo (jpg, 996435)